|

|

|

|

This is my first scooter, a Vespa T4. It took me half a year to open and rebuilt the engine. Now a days the same procedure just takes a few hours only... |

After a while i learned about fluid dynamics and swirls in flows. This effect made it possible to have rings of smoke. Some calculation and design work on exhaust systems brought me to the desired result... |

|

|

|

|

|

....an older projects: PX 200, big tyres (120/90), 28 mm carburator, PSP - Exhaust, 208 ccm Mallossi, long stroke cranc shaft.. and so on..about 21 HP on back wheel.. ;-) |

even prebulit units can be modified and optimized. PX 200 - Leo Vinci exhaust system prolonged |

|

|

|

|

|

Installed and ready to ride ...... hui! but about 10 liters per 100 km fuel consumption :-(( |

Propper

Electrics...

|

|

|

|

|

|

Conversion

of an old Sprint 150 ccm......

|

...now

equipped with a new CDI controlled ignition system..

|

|

|

|

|

|

Calculation, design, construction and crafting of a resonance exhaust system to increase the performance of Vespa PX 200 Scooters |

Other measures to increase the performance of Vespa-Scooters: double carburator with a double intake welded from aluminium. |

|

|

|

|

|

.......Basic

ideas for design and technical solutions....

|

...Thailand

offers many ideas for optic appearance...

|

|

|

|

|

|

..like

this.....

|

....or

that....

|

|

|

|

|

|

@ home: they became two - a boy and a girl

|

same same - but different..

|

|

.jpg) |

|

|

|

@

home of piaggio

|

unidentified

shrinking

|

|

.jpg) |

.jpg) |

|

|

..my newest toy: 130/70 tyres, about 125 km/h, less fuel consumption, just 8 liters! and a microjet above the front wheel, sounds like a jet! |

conversion

80 ccm to all above 125ccm alu - milling!

|

|

.jpg) |

|

|

|

loud and horrible good!! my new exhaust system calculated and designed to malossi 210 ccm EO time 192 degrees |

view

from behind, the Betram 110 model a.m.

|

|

|

|

|

|

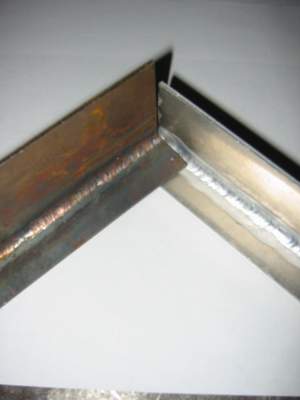

MIG - MAG : Helpful for all type of steel and inox material. I just use it for steel with CO2 |

TIG - Welding: very important for aluminium. Without no high performance, due to small gas path.. |

|

|

|

|

|

Welding

is a type of art - and soooo helpful....

|

ARC

- Welding : For all type of of heavy application and cast iron

|